- / STARTSEITE

- / produkte

Deposition Systems for Compound Semiconductors

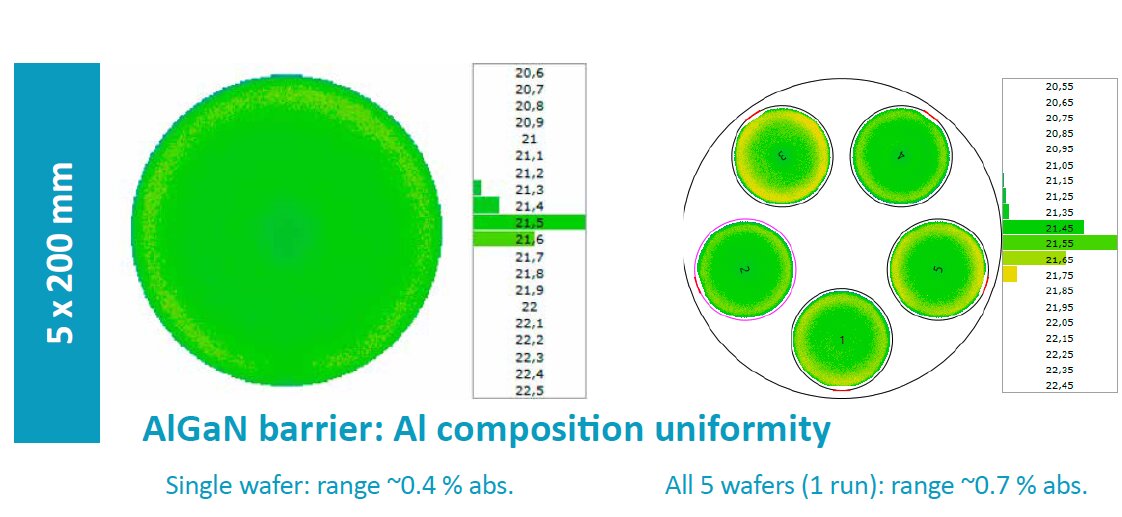

150/200 mm high throughput epitaxy

for GaN power & RF applications

.

Single wafer performance at lowest batch processing cost

FAST CHARGER

Source: https://www.digitalcameraworld.com/buying-guides/best-gan-charger

DATA CENTER

Source: https://www.datacenterknowledge.com

SOLAR MICRO INVERTER

Source: https://www.solarreviews.com

|

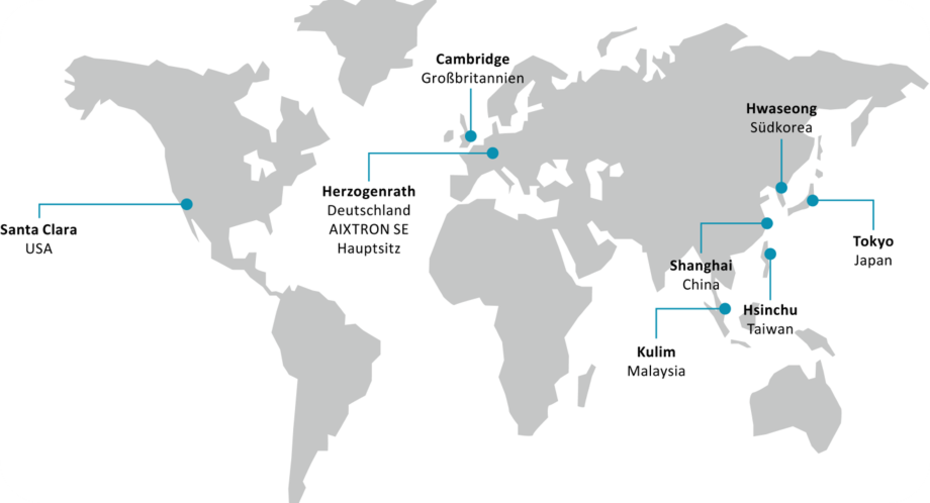

CHINA |

GERMANY |

|

TAIWAN |

KOREA |

|

USA |

UNITED KINGDOM |

|

JAPAN |

MALAYSIA |

Alan Tai

Taiwan/Singapore

Christof Sommerhalter

USA

Christian Geng

Europe

Hisatoshi Hagiwara

Japan

Nam Kyu Lee

South Korea

Wei (William) Song

China

AIXTRON SE (Headquarters)

AIXTRON 24/7 Technical Support Line

AIXTRON Europe

AIXTRON Ltd (UK)

AIXTRON K.K. (Japan)

AIXTRON Korea Co., Ltd.

AIXTRON Taiwan Co., Ltd. (Main Office)

AIXTRON Inc. (USA)

Christoph Pütz

Senior Manager ESG & Sustainability

Christian Ludwig

Vice President Investor Relations & Corporate Communications

Ralf Penner

Senior IR Manager

Prof. Dr. Michael Heuken

Vice President Advanced Technologies

Christian Ludwig

Vice President Investor Relations & Corporate Communications