- / HOME

This Management Report comprises both the Group Management Report and the Management Report of AIXTRON SE. In this report, we inform about the business development as well as the situation and the expected development of the AIXTRON Group (hereinafter also referred to as “AIXTRON”, “AIXTRON Group”, or “the Group”) and AIXTRON SE (hereinafter also referred to as “the Company). The information regarding AIXTRON SE is contained in a separate section in the report on economic position with disclosures in accordance with the German Commercial Code (HGB).

The Consolidated Financial Statements of the Group have been prepared in accordance with International Financial Reporting Standards (IFRS) as adopted by the EU. With the exception of the HGB disclosures in the chapter Management Report of AIXTRON SE, all financial figures contained in this Group Management Report, including the comparative figures for the previous year, are reported in accordance with IFRS.

Further information about the adherence to reporting standards is contained in section “Significant Accounting Policies” of the notes to the Consolidated Financial Statements.

Due to rounding, numbers presented throughout this report may not add up precisely to the totals indicated and percentages may not precisely reflect the absolute figures for the same reason.

AIXTRON’s business activities include the development, production and installation of equipment for the deposition of complex semiconductor materials, the development of deposition processes on such equipment, consulting and training, and customer support and service for such equipment. AIXTRON also provides peripheral equipment and services for the operation of its equipment.

AIXTRON supplies deposition equipment for volume production as well as equipment for research and development (R&D) and pre-series production.

The demand for AIXTRON equipment is significantly influenced by requirements for higher energy efficiency in IT, by the expansion of electromobility, by increasing transmission speeds and volumes of data, as well as by the use of 3D sensor technology in consumer electronics and in the automotive sector, and last but not least, by the use of innovative technologies in displays. The ability of AIXTRON’s technologies to deposit thin material films precisely, enables manufacturers to improve performance, yield and quality in the fabrication process of advanced power- and optoelectronic devices.

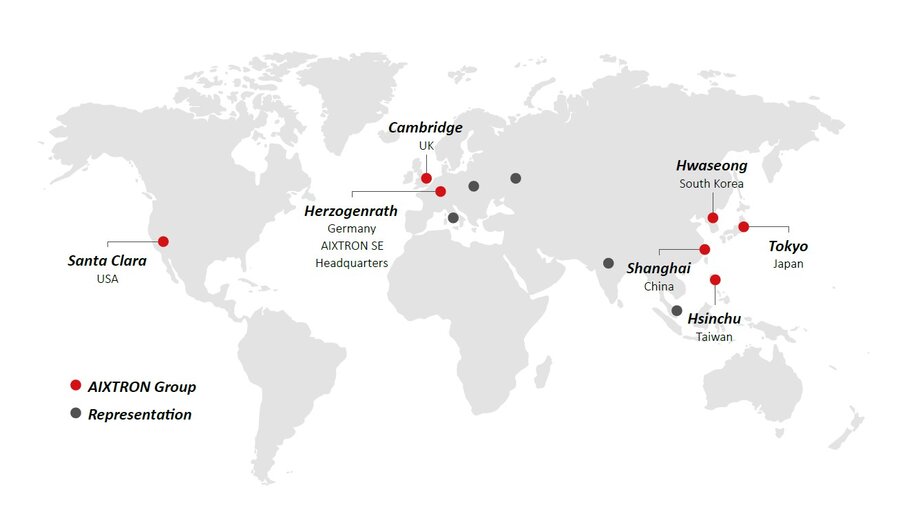

The AIXTRON Group comprises the parent company AIXTRON SE with its registered office in Herzogenrath, Germany, and its subsidiaries. As of December 31, 2021, AIXTRON SE held direct and indirect stakes in 10 companies which are part of the AIXTRON Group, and which are fully consolidated. A list of all consolidated companies is shown in Note 32 of the Notes to the Consolidated Financial Statements.

| Facility location | Use |

|---|---|

| Herzogenrath, Germany | Headquarters, R&D, Manufacturing, Engineering |

| Cambridge, UK | R&D Manufacturing, Engineering, Service |

| Santa Clara, CA, USA | Sales, Service |

| Hwaseong, South Korea | Sales, Service |

| Shanghai, China | Sales, Service |

| Hsinchu, Taiwan | Sales, Service |

| Tokyo, Japan | Sales, Service |

As a European stock company (Societas Europaea) the AIXTRON SE has a dual management and control structure consisting of an Executive Board and a Supervisory Board. The Executive Board is responsible for managing the Company at its own responsibility while being advised and monitored by the Supervisory Board. In 2021, there were the following personnel changes in the Company’s management and supervisory bodies:

Dr Bernd Schulte left the Executive Board at expiration of his contract on March 31, 2021, and retired. As of 1 April 2021, Dr Felix Grawert was appointed Chairman of the Executive Board. Thereafter, the Executive Board briefly consisted only of the two members Dr Grawert and Dr Linck. As of May 1, 2021, Dr. Christian Danninger joined the AIXTRON Group as the new Chief Financial Officer. Since then, the Executive Board has again consisted of three persons. The composition of the Supervisory Board has not changed since December 31, 2020.

Detailed information on the composition of the Executive Board and the Supervisory Board, the allocation of responsibilities between them, the operating procedures of the Supervisory Board committees and the Company‘s diversity concept can be found in the Corporate Governance Declaration according to Section 289f HGB and Section 315d HGB, including the Declaration of Conformity according to Section 161 AktG are part of the annual report and also available on the AIXTRON website at Corporate Governance Statement.

AIXTRON’s product range includes customer-specific systems for the deposition of complex semiconductor materials on a diverse range of different substrate sizes and materials.

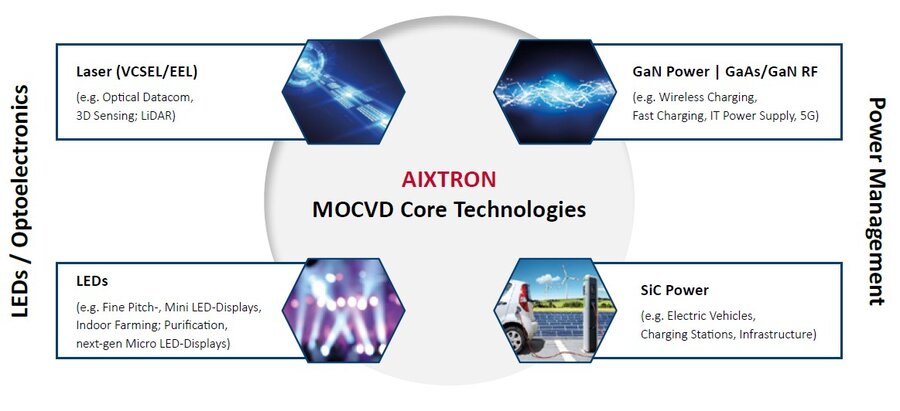

The MOCVD process (Metal Organic Chemical Vapor Deposition) is used for the vapor phase deposition of so-called compound semiconductor materials for the manufacture of power and optoelectronic components.

In the area of power electronics, our systems are used for the production of gallium nitride (GaN) semiconductor devices for more compact and more powerful power supplies in consumer electronics, for the efficient power supply of data centers and mobile communications infrastructure. In addition, our systems are used to manufacture GaN devices for wireless data transmission in mobile communications, currently primarily in the 5G area and soon also in the 6G network. A second major application field of power electronics is silicon carbide (SiC) devices, which are used e. g. in electric vehicles as well as their charging infrastructure and in inverters for renewable energies (solar and wind). These components are also manufactured by our customers with our CVD systems.

Our systems in the field of optoelectronics are used by customers to manufacture lasers for optical data transmission and 3D sensor technology. They are used in smartphone facial recognition, robotic environment sensing, autonomously driving vehicles, and other applications requiring context recognition. Furthermore, our customers use AIXTRON equipment to manufacture pixels in display applications - currently deployed productively in the area of large area displays, and in the future also in the area of Micro LEDs. Other applications of our equipment include the production of specialty LEDs, such as red, orange, and yellow (ROY) LEDs for automotive lighting and indoor farming, among others. UV LEDs for environmentally friendly disinfection of water and air are also included.

AIXTRON is constantly working on the improvement of existing technologies and products. In recent years, AIXTRON has introduced several new system generations and technologies. In addition to the continuous improvement of material performance, the focus is particularly on further optimizing the systems for high-volume production through more automation, such as the fully automated AIX G5+ C for GaN devices or the AIX G5 WW C for next-generation silicon carbide (SiC) applications.

AIXTRON manufactures its prototype and customer equipment at its production sites in Herzogenrath and in Cambridge. Production focuses on assembly, testing, and qualification. The Group procures the components required to manufacture the equipment and the majority of the pre-assembled modules from external suppliers and service providers. The performance of our supply chains is being continuously improved both to secure higher overall demand and to compensate for fluctuating delivery capabilities. On the basis of a rolling forecast, the necessary measures to ensure material availability are taken in close coordination between sales, purchasing and production. This also includes the early identification of bottlenecks in raw materials and components. Together with the partners in the supply chain, suitable strategies are applied to ensure optimum availability while keeping an eye on inventories. The assembly of the equipment is carried out with the help of external service providers in the company's own production facilities or, if required, in rented production facilities and in accordance with AIXTRON’s technical specifications. Subsequent testing and qualification of the equipment is carried out by AIXTRON staff - as is production control and quality assurance throughout the production process.

AIXTRON’s manufacturing facilities have process-oriented quality management systems certified in accordance with ISO 9001:2015. In the year 2021, the certification of the quality management systems of AIXTRON SE and AIXTRON Ltd. was confirmed without any deviation by external auditors.

AIXTRON’s leading position in the global market and its ability to continuously innovate are driven by the commitment and excellent knowledge of our employees. Our human resources management is therefore designed to create an inspiring, safe, and supportive environment, as well as to foster appreciative and cooperative interaction.

Attracting and retaining highly qualified and committed specialists and managers is a key success factor. Competing for the best talent, we are continuously enhancing our attractiveness as an employer brand. In addition to a comprehensive, informative careers site and other communication channels, we use a wide variety of target group-oriented recruitment channels, increasingly in social media. Personal contact with potential applicants at job fairs and similar events, as well as in the context of our close cooperation with universities worldwide, is also of great importance to us.

AIXTRON is working consistently to establish a modern corporate culture with a mature leadership culture and good teamwork. We attach great importance to supporting our employees competently and in a spirit of partnership, to promoting them individually, and to challenging them with future-oriented projects and tasks. As part of our company-wide personnel development concept, we offer our employees a wide range of measures for continuous training as well as individual advanced training measures and development opportunities.

Another central pillar of our corporate culture is AIXTRON’s commitment to diversity and equal opportunities, which form an essential basis for our innovative strength and competitiveness. We explicitly encourage collaboration in mixed teams and between different cultures and nationalities. We also attach great importance to an appropriate gender balance and a balanced age structure.

In the 2021 fiscal year, the number of employees in the Group decreased slightly by approximately 1.4% from 728 at the end of 2020 to 718 as at 31 December 2021. This reflects the reduced headcount resulting from the restructuring of the APEVA Group, which was offset by a significant increase in AIXTRON SE's headcount due to the continued strong growth of the Group's core business. As in previous years, the majority of employees are located in Europe.

AIXTRON’s customers span the power electronics, optoelectronics, and display industries. For example, they manufacture high-performance semiconductor devices for applications in IT infrastructure, consumer electronics, power generation, and for use in the field of electromobility. In the optoelectronics sector, they manufacture lasers for data transmission, consumer electronics and automotive applications, among others. Customers in the display industry, on the other hand, focus among other things on the manufacture of new types of LEDs (Mini and Micro LED) to address displays of all sizes, from smartwatches to large-area display panels. Some of these customers are vertically integrated device manufacturers who serve the entire value chain as far as the end consumer. Others are independent manufacturers of components or epitaxial wafers who deliver the products made on AIXTRON equipment to the next link in the value chain, namely, the electronic device manufacturers. The Company’s customers also include research centers and universities, which particularly promote research into new types of materials.

AIXTRON’s products are distributed worldwide. The market segments vary regionally. Most of the world’s leading electronic device manufacturers produce in Asia and consequently, the majority of AIXTRON sales continue to be delivered into this region.

See also “Development of Revenues” in this report for a breakdown of revenues by region.

With the development, manufacture, distribution and maintenance of thin film deposition systems for complex materials, AIXTRON addresses growing future markets along a variety of end-user applications, such as consumer electronics, automotive, telecommunications, and power generation.

As a technology leader in the field of these complex deposition processes, AIXTRON's strategy is to optimally address each of the many different and rapidly growing end markets through a clear focus on its core competencies, and to reinvest the earnings for the development of further promising future applications.

It is our objective to secure and further expand our market position in the addressed focus markets in the long term through innovation and technology leadership, and to access adjacent markets by leveraging our core competencies. The sustainability of the business, increasing revenues and profitability are the focus of our strategic planning.

The core of AIXTRONs strategy is to diversify its fields of application while maintaining its focus on AIXTRON’s core competencies. The targeting of applications and markets that are attractive to AIXTRON in terms of size, growth, profitability and differentiation potential is currently very successful. This is because these applications from different industries, such as consumer electronics, IT infrastructure and electromobility, are subject to growth dynamics that are largely independent of one another. Thus, AIXTRON does not depend on only one single segment but strives to be robust against fluctuations in individual application markets across the entire range of applications. To this end, AIXTRON actively develops a broad technology portfolio through in-house or sponsored developments, through collaborations, or through targeted acquisitions. The process of maintaining and developing technology ecosystems in close cooperation with customers and, where applicable, their customers or technology partners, allows AIXTRON to establish new technologies and open up new applications.

AIXTRON focuses on markets where the use of AIXTRON technology allows for a clear differentiation from competitors and thus creates value added for customers. These include, among other things, achieving high yields on the wafer by realizing high uniformity of the physical properties of the deposited layers while simultaneously maintaining high throughput, low material and maintenance costs. An essential differentiating factor is the high productivity and cost efficiency of our systems, e. g. through high throughput of the systems thanks to the so-called batch reactor, in which several wafers can be produced simultaneously, or through the reactor architecture-related efficiency of material usage. Markets with not enough potential for technical differentiation offer only low margins.

AIXTRON pursues a platform strategy with its AIX 2800G4 and AIX G5 and AIX G5 WW families of systems that are based on the planetary concept. With a high proportion of identical parts, the systems can be configured according to customer’s specification. As outlined in the previous section, this allows for a broad diversification and the addressing of numerous applications. In addition to the AIX 2800G4, AIX G5 and AIX G5 WW system families, which address customers with high production volumes, AIXTRON sells a showerhead-based system series, to universities and niche markets. This allows AIXTRON to come into contact with emerging applications at an early stage and to understand customer needs in new markets.

Our OLED subsidiary APEVA was initially restructured in the second quarter of 2021 and focused on the Chinese market. However, as customers in this market are also opting for Micro LED as the technological basis for the development of the next generation of displays even faster than originally expected, the shareholders of APEVA have decided not to invest further in APEVA.

Since the various activities of the Group are largely integrated from an operational perspective, management by means of performance indicators is carried out by the Executive Board of AIXTRON SE at Group level. The Executive Board's development projections for the Group therefore also apply to AIXTRON SE.

The most relevant performance indicators for the AIXTRON Group are order intake, revenues, gross margin and earnings before interest and taxes (EBIT) relative to revenues (EBIT margin). They are determined monthly in the AIXTRON reporting system and made available to management in a comprehensive report. This enables the Executive Board to identify growth drivers at an early stage, to analyze developments during the year and take prompt countermeasures in the event of any discernible deviations.

AIXTRON aims to achieve organic revenue growth, exchange rate effects are excluded when setting revenue targets. Order intake reflects the investment behavior of our customers and thus serves as an early indicator for revenues. The period between receipt and delivery of an order for an MOCVD system is generally between six and eight months.

Gross margin, which expresses gross profit in relation to sales, provides information on the profitability and return on investment of AIXTRON’s operating business. The EBIT margin is used as an additional important indicator for operational management and analysis of the earnings situation.

Since the introduction of the new Executive Board remuneration system in fiscal year 2020, AIXTRON has defined annual sustainability targets for the Executive Board as part of the Long Term Incentive (LTI), which are to be achieved over a three-year reference period, and includes corresponding non-financial performance indicators in the Group management.

The following non-financial performance indicators have been defined for the LTI reference periods 2020 to 2022 and 2021 to 2023 starting in fiscal years 2020 and 2021 respectively:

(measured in kWh standardized to the most important consumption drivers)

(measured in hours of training completed)

New non-financial performance indicators have been defined for the LTI reference period starting in fiscal year 2022. Essentially these are:

The adoption of the new sustainability criteria of the EU Taxonomy Regulation in the Executive Board's LTI performance indicators in fiscal 2022 is intended to ensure the environmental sustainability of the company's activities, particularly in light of the expected growth of the company. The non-financial performance indicators defined for the LTI tranches starting in 2020 and 2021 become secondary with the introduction of the EU Taxonomy Regulation and are no longer considered essential for the implementation of the corporate strategy. Nevertheless, management continues to attach great importance to improving these performance indicators also in the medium and long term.

In addition to the R&D center at its headquarters in Herzogenrath, AIXTRON also operates a R&D laboratory in Cambridge, United Kingdom. These in-house laboratories are equipped with AIXTRON systems and are used to research and develop new equipment, materials and processes for the production of semiconductor structures.

The Group's R&D activities in 2021 again included development programs for future technologies and new products, as well as continuous improvement of AIXTRON's existing products. In order to increase industrial maturity and repeatability, products were optimized along the entire value chain as well as maintenance intervals were optimized via strategic approaches, e.g. through design improvements of externally supplied components or through improved data analysis. In addition, AIXTRON is working on customer-specific development projects and researching new technologies, often in the context of publicly funded projects.

The Group’s R&D capability remains of important strategic significance, as it provides for a competitive, leading edge technology portfolio and supports the future business development. There-fore, AIXTRON is committed to investing specifically in research and development projects to retain or to expand the Company’s leading technology position in MOCVD equipment for applications such as lasers, Micro Leds, specialty LEDs and for the production of wide-band-gap materials for power electronics. In addition, the Group is working on novel 2D nanostructures, which are seen as having great potential in research in line with international predictions (roadmaps).

For the consistent technological evolution of our product portfolio, we have invested EUR 56.8 million, or around 13% of revenues, in research and development (R&D) in 2021. At year-end 2021, 223 of AIXTRON Group’s total 718 employees were engaged in research and development activities.

AIXTRON aims to secure its technology by patenting and protecting inventions, provided it is strategically expedient for the Company to do so. As of December 31, 2021, the Group had 269 (thereof AIXTRON SE: 243) patent families available (December 31, 2020: 274 patent families). For 9 patent families (AIXTRON SE: 7), patent protection was applied. Usually, patent protection for inventions is applied for in those markets relevant to AIXTRON, specifically in Europe, China, Japan, South Korea, Taiwan and the United States. AIXTRON's patent portfolio is evaluated annually and adjusted accordingly. The individual patents expire between 2022 and 2041. In addition, AIXTRON continuously performs a worldwide patent analysis in order to identify and assess changes in the competitive environment at an early stage.

AIXTRON is working on targeted research projects in areas that are considered to have growth potential in the future. The “MOCVD 4.2” project aimed to increase the production suitability of our technology for applications in power electronics in particular, as well as in photonics and sensor technology. An improvement in MOCVD technology and effectiveness was achieved to meet the international requirements of a versatile, highly flexible key technology with frequently changing customer requirements, processes, products and material systems. The project was successfully completed in December 2021. The “MehrSi” research project to increase yield in solar cells was also successfully completed in 2021 with all key project targets achieved. Thus, a central stage in the development of economic solutions for the industrial use of multi-junction solar cells for power generation was reached. Initial results are available for our “AdaptAR” research project, in which an augmented reality system with a digital twin as a data basis is being developed, and our 2D Experimental Pilot Line “2D-EPL” initiative as part of the European Commission's “Graphene Flagship” project is running according to plan and with great promise. A new facility has been constructed here and is currently under construction.

Examples of the Group's research work include the “NeuroSys”, “OIP4NWE” and “AIIR-Power”, on which AIXTRON worked intensively in 2021:

As a partner of the future cluster "NeuroSys - Neuromorphic Hardware for Autonomous Artificial Intelligence Systems", AIXTRON is responsible for building and optimizing the necessary MOCVD systems for the new application. "NeuroSys" researches adaptive and energy-efficient neuromorphic AI chips with the aim of enabling intelligent and resource-efficient on-site data processing, thus creating an essential prerequisite for artificial intelligence (AI) applications. This is considered the key to the widespread use of AI, especially in autonomous vehicles, medical technology and sensor networks for intelligent production or urban regions. Very thin layers of novel 2D materials, only a few atomic layers thick, are needed as the material basis for the neuromorphic chips. The production of these materials on the largest possible wafers is AIXTRON's core competence. As part of this and other projects, AIXTRON will develop the world's most powerful technology platform for the industrial production of these materials and operate it in its laboratory in Herzogenrath.

The project “OIP4NWE - Open-Innovation Photonics pilot for NEW” is researching Integrated Photonics together with TU Eindhoven. This new technology has the potential to revolutionize communication technology, medical diagnostics and measurement technologies. A newly developed automated MOCVD reactor for optimal layer quality and with high productivity is now available for research and pilot production of optoelectronic integrated circuits in Eindhoven.

The “AIIR-Power” project, newly launched in 2020, aims to develop AI techniques to optimize optoelectronic device designs and their epitaxial fabrication, and apply them to realize PPCs (photonic power converters) for telecom wavelengths.

Ubiquitous digitization, automation, and the Internet of Things require constant power and data flows. With the emerging technology of photonic power transfer, also known as "power by light," power and data transfer can be combined in a single optical link, enabling electrically isolated, interference-free remote operation. By using optical telecommunication wavelengths, the potential applications of such power-by-light systems can be extended to new remote locations not previously considered, and unlimited remote power can be provided.

The unique capabilities of the project partners from Canada and Germany create synergies that would be inaccessible to either subgroup alone.

Alan Tai

Taiwan/Singapore

Christof Sommerhalter

USA

Christian Geng

Europe

Hisatoshi Hagiwara

Japan

Nam Kyu Lee

South Korea

Wei (William) Song

China

AIXTRON SE (Headquarters)

AIXTRON 24/7 Technical Support Line

AIXTRON Europe

AIXTRON Ltd (UK)

AIXTRON K.K. (Japan)

AIXTRON Korea Co., Ltd.

AIXTRON Taiwan Co., Ltd. (Main Office)

AIXTRON Inc. (USA)

Christoph Pütz

Senior Manager ESG & Sustainability

Christian Ludwig

Vice President Investor Relations & Corporate Communications

Ralf Penner

Senior IR Manager

Christian Ludwig

Vice President Investor Relations & Corporate Communications

Prof. Dr. Michael Heuken

Vice President Advanced Technologies