- / HOME

We see the protection of the environment as a key factor in the sustainability of our business model and align our actions accordingly. In addition, we are in close contact with our customers and suppliers. Our innovative technologies and products, on which our success is based and whose efficiency and performance convince our customers worldwide, make a decisive contribution.

Our customers benefit from forward-looking solutions that save costs, conserve resources, and are energy-efficient in equal measure. Our customers include companies from the areas of electromobility (drive trains, charging infrastructure), renewable energies (network circuits), IT infrastructure (power supply), consumer electronics (3D sensors, fast chargers) as well as data transmission (fiber optic networks) and telecommunications (5G network).

We also make a significant contribution to digital progress in the areas of display technology (mini and Micro LEDs), lighting and UV radiation for disinfection/hygiene. Components for a variety of innovative applications, technologies and industries are manufactured on AIXTRON systems.

With the Action Plan on Sustainable Growth, the EU Commission aims to make the economic and financial system in the EU more sustainable. Climate neutrality should be achieved by 2050, i.e. the same amount of CO2 emissions should then be avoided or eliminated as is emitted. The core of this action plan is the EU taxonomy regulation, a standardized classification system for sustainable economic activities. It defines six environmental goals:

According to EU taxonomy guidelines, economic activities are “environmentally sustainable” if they

Whether an economic activity makes a significant contribution to one of the goals and does not significantly affect the five other goals must be assessed using technical assessment criteria. In the 2023 financial year, information on how they can be allocated to the environmental goals must be provided for all six goals. In the previous year, information only had to be provided on the first two objectives in terms of their taxonomy eligibility and taxonomy conformity.

Against the background of the EU Taxonomy Regulation, in the 2023 financial year we will report on the taxonomy-eligible and taxonomy-aligned share of sales revenue, capital expenditure (CapEx) and operating expenses (OpEx) of our economic activities. The individual values can be found in the reporting forms in the Key figures chapter.

Method

As in the past two years, the EU taxonomy requirements were reviewed and analyzed in the 2023 reporting year with the help of a project team in relation to the six EU environmental goals.

In the first step, the project team, which consists of experts from various disciplines, confirmed that the economic sector “Manufacture of machines for other specific economic sectors a.n.g.” (NACE Code 28.99) and the economic activities of the “Construction and Real Estate” category are currently applicable to AIXTRON.

In addition, we report 3.6 CapEx and OpEx B in connection with economic activities in accordance with paragraphs 1.1.2.2 and 1.2.3.2. of Annex I of Delegated Act (EU) 2021/2178. This includes investment expenditure for the construction of a new innovation center, which will serve to expand our taxonomy-compliant economic activities in the future. In addition, research activities for the expansion of technologies are reported under economic activity 3.6.

Interviews and workshops with the respective contacts and experts from the departments were then used to check whether our economic activities could be assigned to the taxonomy descriptions (eligibility check).

The experts' assessments were documented for sales, CapEx and OpEx and the relevant evidence and supporting documents were examined. The analysis was carried out taking into account materiality aspects and cost/benefit considerations. AIXTRON has identified the environmental goal “1 climate protection” as applicable. No taxonomy-eligible economic activities within Environmental Goals 2 to 6 were identified. The following economic activities were identified as eligible for taxonomy:

Unlike criteria sets 3.1, 7.3 and 7.6, criteria set 3.6 contains a higher number of terms that require interpretation and are defined below. The set of criteria “Production of other low- CO2 technologies” is of particular relevance for the supplier industry in mechanical and plant engineering. This set of criteria includes economic activities that produce technologies that aim to achieve significant savings in life-cycle greenhouse gas emissions and are proven to achieve them compared to the best performing alternative technology available on the market.

For the identification of taxonomy-eligible economic activities that fulfill the description of activity 3.6, those technologies were identified from AIXTRON's technology portfolio that have low CO2 emissions in their application. The reduction in greenhouse gas emissions must be significant. However, no minimum value is specified.

It can be assumed that the purpose pursued with the "EU Action Plan on Financing Sustainable Growth" is to focus on technological leaps rather than efficiency increases within the existing system: A saving of 20% should regularly be significant and thus a significant one contribute to climate protection. AIXTRON has set this value as the minimum value for significant savings in CO2 emissions. A reference technology is the technology that dominates the market and not a possibly very efficient niche technology with only a very small market share. With regard to the reference standard, we therefore only used this reference technology for the evaluation.

The analysis of the taxonomy conformity was carried out as follows:

As part of this analysis, the following taxonomy-eligible and at the same time taxonomy- eligible and/or aligned economic activities were identified at AIXTRON, which make a significant contribution to environmental goal 1. Climate change mitigation.

Production of other low-CO2 technologies (3.6)

AIXTRON develops, produces and sells systems for the deposition of compound semiconductors. This separation is the essential step in the production of compound semiconductors, which contribute significantly to avoiding energy losses and thus to a significant saving of CO2. The savings were determined through life cycle assessment (LCA) and confirmed by an independent third party.

Power semiconductors with a wide-band- gap (WBG) based on gallium nitride (GaN)

GaN power transistors make a significant contribution to energy savings compared to established silicon-based technology through significantly reduced energy losses in the conversion of current and voltage (e.g. when charging mobile devices or in power supplies and switches in the power grid or in data centers) a significant contribution to energy savings compared to established silicon-based technology.

AIXTRON enables research into more energy-efficient power transistor designs and enables industry to mass produce the new devices.

Power semiconductors with a wide-band- gap (WBG) based on silicon carbide (SiC)

SiC power transistors make a significant contribution to energy savings compared to established silicon-based technology by significantly reducing energy losses when converting current and voltage (e.g. when charging electric vehicles or switching drives in locomotives).

AIXTRON enables research into more energy-efficient power transistor designs and enables the mass production of the new devices by industry.

Micro LEDsfor next-generation displays

Micro LEDs make a significant contribution to energy savings by reducing the energy consumption of displays by up to 90% compared to established LCD technology. The imaging is done selectively, i.e. H. Light is only generated in the pixels needed to display the image. Black areas of the image remain dark and do not consume any energy, whereas conventional technology requires the shading of a permanently bright backlight. AIXTRON enables the mass production of new displays based on Micro LEDs by the industry.

Laser diodes for data communication

The transition from wired to optical telecommunications, especially in the “last mile”, contributes significantly to reducing the energy consumption of telecommunications networks while increasing data throughput. AIXTRON enables research into more energy-efficient and faster laser diode designs and enables the mass production of the new fiber-optic modules by industry.

Manufacturer data was used to calculate the LCA.

Manufacture of renewable energy technologies (3.1)

AIXTRON develops, produces and sells systems on which compound semiconductors are made that generate electricity from solar energy.

Solar cells

Compound semiconductors for concentrator photovoltaic (CPV) solar cells are much more efficient at generating electricity from solar energy than conventional crystalline silicon-based solar cells. Solar cells made from compound semiconductors are often used for high-tech applications such as B. used in space travel.

With regard to the EU environmental target 2. Climate change adaptation, there are no indications that the adverse effects of climate change will adversely affect AIXTRON's business operations. The AIXTRON production sites are not subject to any significant physical climate risks.

The criteria for the EU environmental target 3. Sustainable use and protection of water and marine resources essentially relates to legal and official requirements that AIXTRON is obliged to comply with. Water is not used to any significant extent in the production process at AIXTRON. The systems are to be kept away from water.

With regard to environmental goal 4. Transition to a circular economy, there are general requirements such as long usability, easy maintenance or dismantling. Most of the components are designed for very long service life, can be recycled and still have a monetary value at the end of their useful life (e.g. steel, stainless steel, aluminium, copper, electronics).

Regarding to the EU environmental goal 5. Pollution prevention and control, there are no indications that AIXTRON is violating the corresponding specifications. AIXTRON does not manufacture, place on the market or use substances listed in Appendix C in terms of the taxonomy specifications.

With regard to the EU environmental goal 6. Protection and restoration of biodiversity and ecosystems, environmental impact assessments and assessments are carried out where there is a corresponding requirement.

Information on compliance with the minimum requirements with regard to occupational safety and human rights can be found in the "Occupational health and safety" chapter and in the "Conflict minerals" chapter in this report and on the AIXTRON website in the sustainability section.

To determine the key figures (KPIs) to be reported, the taxonomy-eligible and taxonomy- aligned net revenues, investments (CapEx) and operating expenses (OpEx) are set in relation to the total net revenues, the total investments or the total operating expenses to be taken into account according to the taxonomy specifications. The definition of the respective KPI is based on the appendices of the Delegated Act to Article 8 on the content and presentation of the information to be disclosed.

Double counting on single environmental goals is avoided by clearly assigning the taxonomy-eligible or taxonomy-aligned revenues, CapEx and OpEx to a taxonomy-eligible or taxonomy-aligned economic activity.

Revenue within the meaning of the EU Taxonomy Regulation is defined as net revenue in accordance with International Financial Reporting Standards (IFRS) as reported in the consolidated income statement and relates only to fully consolidated subsidiaries. Further information on sales revenue can be found in the “Sales development” section of the economic report in the combined management report of the AIXTRON Annual Report 2023.

The majority of taxonomy-aligned AIXTRON sales revenue can be assigned to taxonomy criteria set 3.6.

CapEx as defined by the EU Taxonomy Regulation is calculated on a gross basis in accordance with International Financial Reporting Standards (IFRS), i.e. without taking depreciation and amortization into account. CapEx comprises investments in non-current intangible or tangible assets as shown in the statement of changes in non-current assets in the notes to the consolidated financial statements in the annual report. The advance payment for the new innovation center was reported under CapEx B of the EU taxonomy in the current reporting year.

The CapEx plan for the innovation center serves to expand economic activity 3.6 and thus relates to the environmental objective "1 Climate protection", in which the capacities for research and development are expanded. The total investment volume amounts to around EUR 100 million (of which EUR 30.9 million in 2023) and is expected to be completed by the beginning of 2025. Further information on CapEx can be found in the "Financial position" and "Investments" sections of the economic report in the combined management report of the AIXTRON Annual Report 2023.

The numerator for taxonomy-aligned CapEx corresponds to the part of CapEx A and B contained in the denominator within the meaning of Article 1.1.2.2 of Delegated Regulation (EU) 2021/2178 that relates to assets associated with taxonomy-aligned economic activities.

The numerator for taxonomy eligibility corresponds to the part of CapEx A, B and C contained in the denominator within the meaning of the EU Taxonomy Regulation that relates to assets associated with taxonomy-eligible economic activities. CapEx C was verified on the basis of information provided by the supplier.

OpEx as defined by the EU Taxonomy Regulation includes non-capitalizable research and development costs that are recognized in the consolidated income statement as well as additional expenses for short-term leases and expenses for building renovation measures, maintenance and repair in accordance with International Financial Reporting Standards (IFRS). Expenditure on technologies not yet launched on the market was reported under OpEx B of the EU taxonomy in the current reporting year. The total project volume amounts to approximately EUR 28.9 million (of which EUR 8.4 million in 2023).

The numerator for taxonomy-aligned OpEx corresponds to the part of the operating expenses included in the denominator that relates to OpEx A and B within the meaning of the EU Taxonomy Regulation that are associated with taxonomy-aligned economic activities.

The numerator for taxonomy eligibility corresponds to the part of the operating expenses included in the denominator that relates to OpEx A and B within the meaning of the EU Taxonomy Regulation that are associated with taxonomy-eligible economic activities.

Other OpEx within the meaning of Article 1.1.3.2. c) of Commission Delegated Regulation (EU) 2021/2178 of July 6, 2021 is not given.

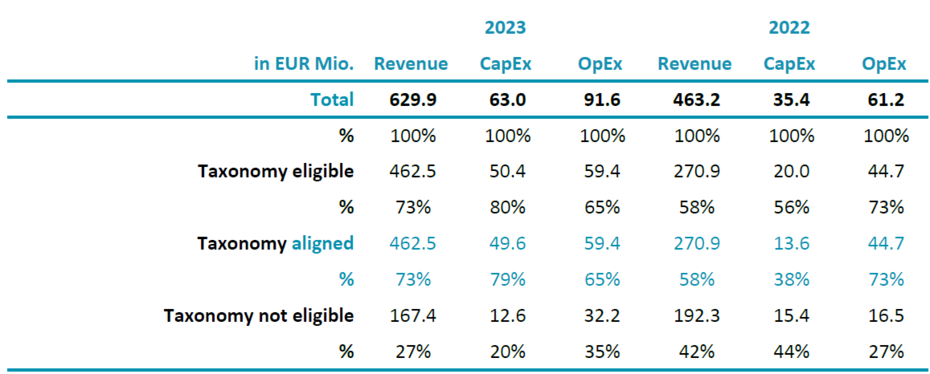

In the 2023 reporting year, the taxonomy-aligned share of sales increased by 15pp to 73%, which is mainly due to business development (2022: 58%). Further information on business development can be found in the AIXTRON Annual Report 2023. As in the previous year, taxonomy-aligned revenues of EUR 462.5 million in the 2023 reporting year include revenues from business activities in accordance with 3.1 and 3.6. As in the previous year, both taxonomy-eligible and taxonomy-aligned revenues relate exclusively to revenues from contracts with customers.

The taxonomy-aligned CapEx share increased by 41pp to 79% in the 2023 reporting year (2022: 38%) and amounted to EUR 49.6 million (2022: EUR 13.6 million). This increase is primarily due to the down payment for the new innovation center. Of the taxonomy- aligned shares, EUR 49.6 million (2022: EUR 13.3 million) is attributable to additions to property, plant and equipment and EUR 0.02 million (2022: EUR 0.3 million) to additions to intangible assets.

The taxonomy-aligned CapEx in the 2023 reporting year amounting to EUR 49.6 million includes investments from economic activities in accordance with 3.6 (2022: 3.1 and 3.6). They are made up of CapEx A in the amount of EUR 18.7 million and CapEx B in the amount of EUR 30.9 million. In 2022, the taxonomy-compliant additions in the amount of EUR 13.6 million are based exclusively on CapEx A.

The taxonomy-eligible CapEx in the 2023 reporting year of EUR 50.4 million (2022: EUR

20.0 million) includes additions to property, plant and equipment in the amount of EUR

50.4 million (2022: EUR 14.0 million) and additions to intangible assets in the amount of EUR 0.02 million (2022: EUR 0.3 million). In 2022, capitalized rights of use in the amount of EUR 7.0 million were reported as taxonomy-eligible. The taxonomy-eligible investments in the 2023 financial year relate to economic activities 7.3 and 7.6 (2022: 7.3, 7.6 and 7.7).

The taxonomy-aligned OpEx share fell by 8pp to 65% in the 2023 reporting year (2022: 73%). Compared to the previous year, less research and development expenditure was classified as taxonomy-aligned in the current reporting year. As in the previous year, the taxonomy-aligned OpEx of EUR 59.4 million in the 2023 reporting year exclusively includes research and development expenses and was allocated to economic activities in accordance with 3.1 and 3.6 (2022: 3.1 and 3.6).

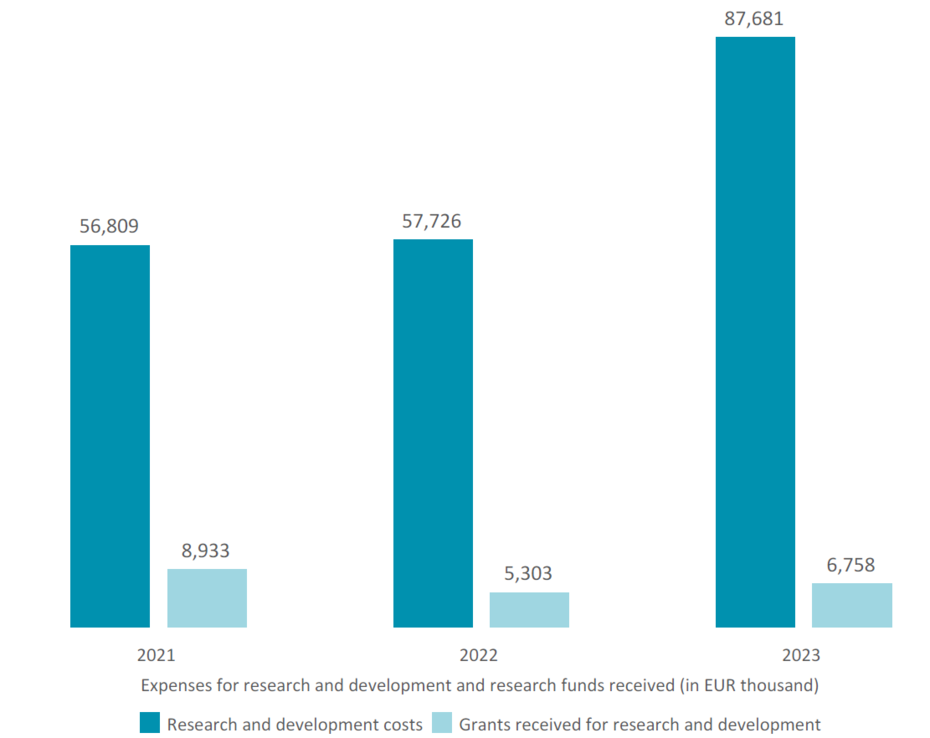

For us, new technologies are the result of targeted investments in our research and development. In this context, the groundbreaking ceremony for the new innovation center took place in November 2023 at the Herzogenrath location with an investment volume of around EUR 100 million. The R&D process starts with basic research on materials and then moves on to processes and procedures. A key result of our research work is our innovative product portfolio with technology solutions that enable our customers to manufacture products that save greenhouse gas emissions during their use.

We work together with predominantly renowned universities, research centers, and industrial partners around the world in order to implement demanding projects on a national and international level in partnership. We benefit from the fact that we can work together with qualified partners, but at the same time, we are also in demand as a partner for research projects.

When developing innovations for materials and processes, we work together with our partners in nationally or Europe-wide funded joint projects. In close cooperation, solutions are created that should lead to marketable products.

In the section "Research and Development" section of the AIXTRON Annual Report 2023, you will find some examples of research projects in which AIXTRON is involved.

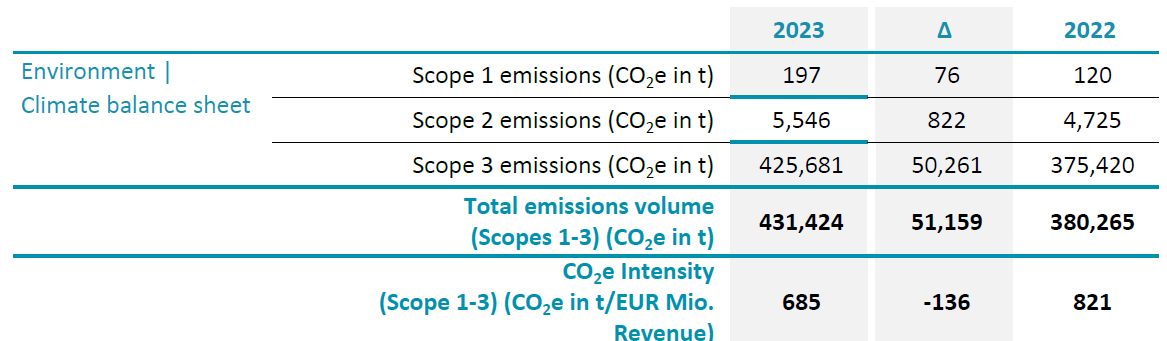

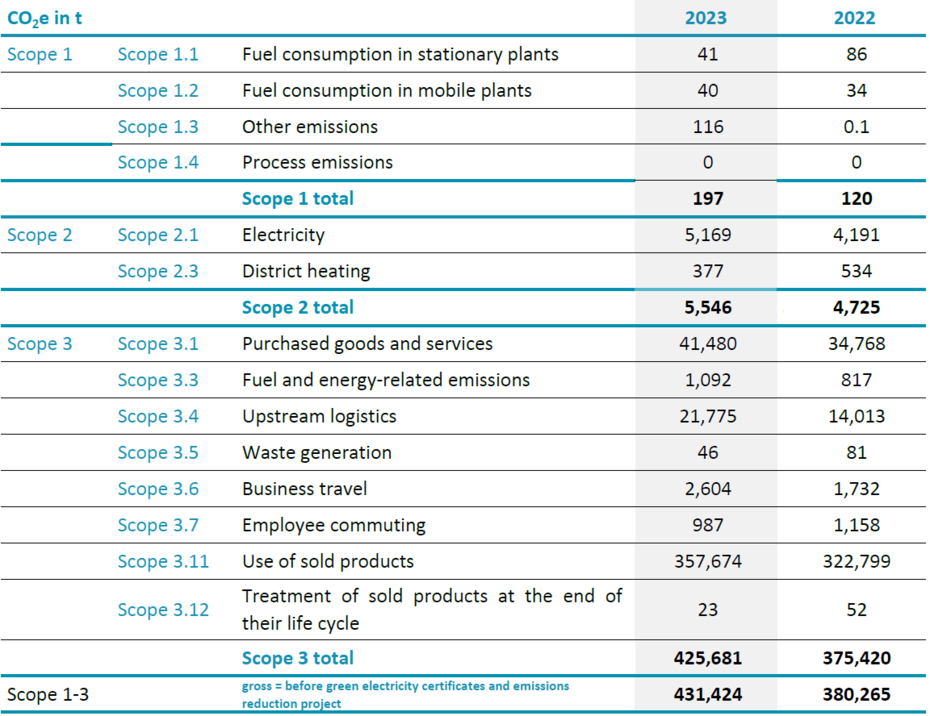

For the reporting year 2023, AIXTRON reports all emissions in the corresponding scopes in which the necessary information is available. Total emissions of 431,424t CO2e were determined (gross = location based) (2022: 380,265t CO2e). Scope 3.11 emissions were reported for the first time in the financial year. These were also determined for the previous year and the reported values were adjusted accordingly.

The total emissions figure for 2023 as a whole is therefore higher than the figures calculated for 2022. Reasons for this increase include the increased business volume and production capacity utilization. CO2e intensity has fallen significantly compared to 2022 by -136 tons per EUR million in sales.

Overview of CO2 emissions [in tons of CO2e] / Emissions for electricity (gross = location based)

* To standardize the climate impact of the different greenhouse gases, we use the representation of the CO2 equivalents (CO2e) as the unit of measurement.

For Scope 2.1 emissions "Electricity" (location-based), the gross value was used this year. The values from the previous year in this category were adjusted accordingly and also reported in gross. Scope 3.8-3.10 and 3.13-3.15 do not apply to AIXTRON. A separate disclosure of Scope 3.9 is not possible due to the data situation. In principle, the values were calculated on the basis of consumption or determined quantities. The value-based approach was chosen in Scope 3.1 for the areas of healthcare/social services, service/consulting and software, as it is not possible to express the data in kilograms for these categories. Instead, metrics based on euro values were used to present the relevant information. The quantities in Scope 3.11 in kWh refer to a life cycle of the machines of 10 years.

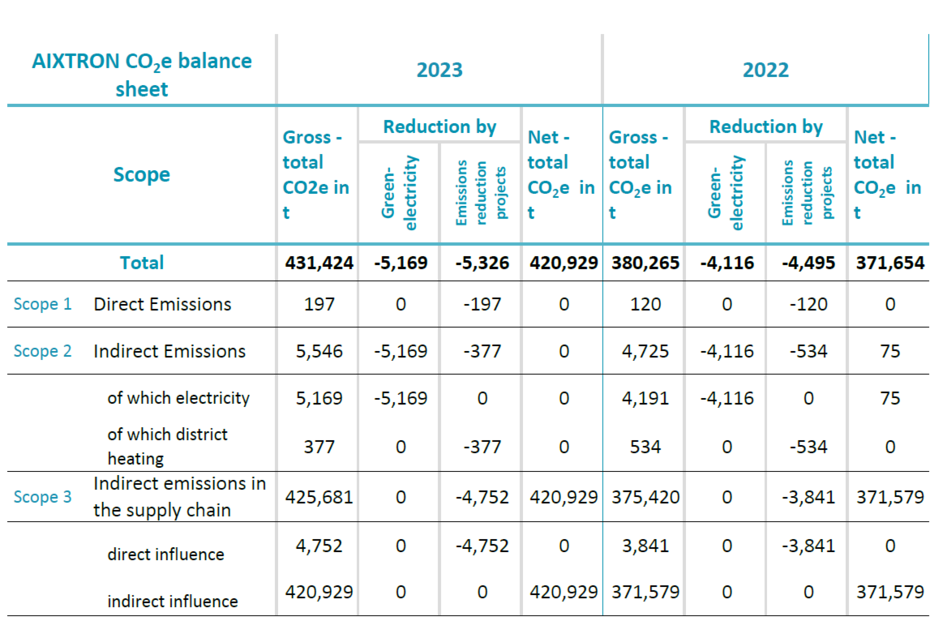

In addition to technical measures to reduce emissions, such as heat pumps and LED lighting, we are reducing our carbon footprint based on gross emissions by using green electricity from green electricity certificates at all locations for the first time in 2023. In order to minimize our ecological footprint, we offset unavoidable emissions by supporting a certified emissions reduction project.

direct influence = can be influenced by AIXTRON without the involvement of third parties (3.3, 3.5, 3.6, 3.7, 3.12) indirect influence = can only be influenced by AIXTRON with the help of third parties (3.1, 3.4, 3.11)

In the 2023 reporting year, we are supporting an emissions reduction project - a solar park in India. In doing so, we want to reduce the unavoidable CO2e emissions of our business activities (Scopes 1 and 2 and parts of Scope 3). Project support currently extends until 2025 and is verified according to the highest available standards. The project in Andhra Pradesh is a 500 MW solar park that will avoid around 1 million tons of CO2 annually.

AIXTRON strives to sustainably reduce its own energy requirements at its locations while simultaneously growing. To support this project, an energy management system based on the ISO 50001 standard has been implemented at AIXTRON SE's German locations since 2014. The function of this system was determined by the external auditor during the last recertification in April 2023 and the certificate was extended for a further three years.

At the Dornkaulstrasse location, the newly installed heat pump was included in the cloud- based energy management software in 2023. This means that all data on performance, consumption and operation can now be tracked, evaluated and compared with historical data, regardless of location.

As a further project, our own metering systems were installed to monitor consumption in rental properties used by AIXTRON. These can provide real-time transparency about your own energy consumption and also enable direct control options in the future to further optimize energy management.

Since 2023, AIXTRON has been committed to increasing energy awareness, especially among new employees: On-boarding via AIXTRON's own training platform not only provides information about energy management at AIXTRON, but also contains practical energy-saving and environmental tips. The tips can be applied directly at work and some are also suitable for imitation at home. This is intended to promote energy- and environmentally conscious behavior in the long term.

Electricity from renewable energy sources and photovoltaics

Since the reporting year, we have only purchased gray electricity with green electricity certificates at all locations. In addition, we have already installed a photovoltaic system at our Kaiserstrasse location. 100% of the electricity generated in 2023, amounting to 3,408 kWh, will be fed into the electricity grid.

Derived from our systematic energy management, we have already initiated and implemented many projects and measures with the aim of sustainably reducing energy consumption. The most important projects of the past year are listed here as examples:

New 4-pipe air heat pump compensates for gas consumption

For a number of years, we have been successfully using waste heat from the cooling processes in our laboratories at our central location in Herzogenrath, and using it specifically for heating the building. It has already been possible to save 90 percent of gas and 10 percent of electricity consumption. A new 4-pipe air heat pump was installed at the end of 2022, which will avoid most of the remaining gas consumption. The device is the latest technology available on the market: the combination device can be used for both cold and hot water production. To do this, it uses independent and mutually closed circuits. This enables us to further reduce the footprint of CO2 emissions that we directly cause.

State-of-the-art lighting technology creates even more energy efficiency

AIXTRON replaced the existing lighting systems at its worldwide locations with the latest LED lighting technology in 2023. This will enable us to further reduce energy consumption

* When calculating the energy and CO2 savings, we were advised by external companies who gave us technical advice with their engineering knowledge and specialist know-how. All calculations were based on a systematic and scientifically sound approach with specific assumptions for the calculations.

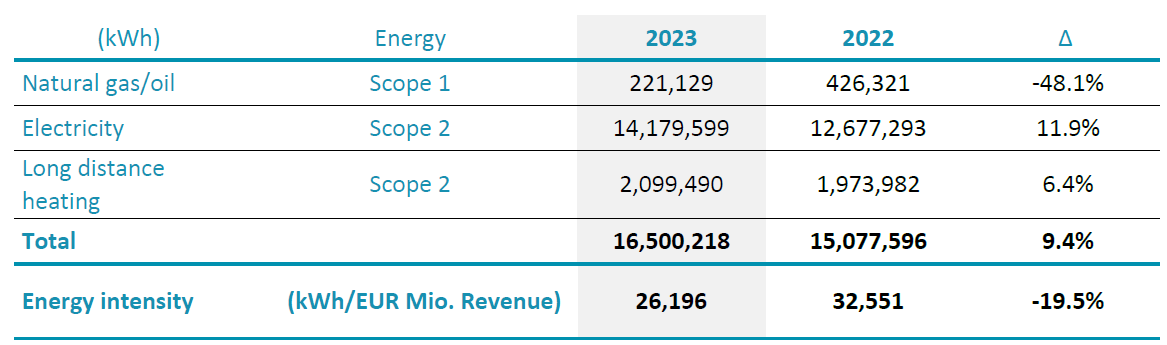

In the past fiscal year, we were able to increase our revenues significantly, which was accompanied by a higher demand for electricity. However, thanks to the various energy- saving projects, we were able to mitigate the increase in overall consumption. Energy requirements rose by 9.4% in the past financial year, with energy consumption per EUR million in revenues falling by 19.5%.

Our successes are confirmation and incentive at the same time: Every year we review our status quo and set ourselves new, ambitious energy-saving targets. At the same time, this is also an economic consideration for us, because the lower consumption also reduces our costs.

We are constantly developing our measures to increase energy efficiency. Our targets relate primarily to our research and production sites in Germany and the UK.

The electricity requirement in 2023 was with 14,179,599 kWh higher than in 2022 (12,677,293 kWh). The reason for this was the continued strong growth in business volume and the continuing good order situation.

The demand for fossil fuels (218,789 kWh natural gas and 2,340 kWh fuel oil) and district heating (2,099,490 kWh) has fallen significantly to a total of 2,320,619 kWh compared to 2022 (2,400,303 kWh). This is proof of the effectiveness of our ambitious energy management and our strategy of using waste heat and state-of-the-art heat pumps.

Energy consumption in the AIXTRON Group for heating, district heating and electricity

Even though AIXTRON strives to use resources sparingly, waste cannot yet be completely avoided in our processes. Sources include, in particular, delivery packaging, offcuts, leftover consumables, but also leftovers from repair, renovation or construction activities or experiments.

In order to return as much of the waste generated by AIXTRON as possible back into the recycling cycle, the waste is separated according to type. To this end, a pictorial labeling system began to be rolled out in productive areas in 2023. This made the separation more transparent in practice.

When disposing of our waste, the focus is on bringing the waste materials into appropriate recycling processes. We work with waste disposal companies that are certified as specialist waste disposal companies. We prefer regional disposal methods here. We want to limit transport routes to a minimum and at the same time ensure a high level of reliability.

Hazardous waste that has to be removed from the recycling cycle due to its properties is eliminated. This is done using officially approved disposal methods so that they do not cause any harm to the environment or people. Using our physical-chemical expertise and working with external experts, we strive to keep the amount of hazardous waste that needs to be disposed of as low as possible. This happens, for example, through the use of suitable cleaning or treatment processes.

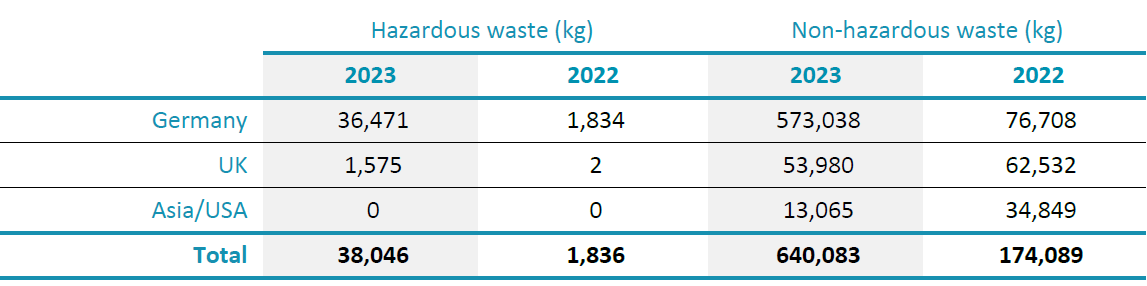

The increased amount of hazardous and non-hazardous waste in Herzogenrath (D) and Cambridge (UK) is due to the increase in production volume. In Germany, the amount of waste disposed of by municipalities was also recorded for the first time in 2023.

Hazardous and non-hazardous waste by region. Used more precise capture method in 2023. Municipal disposal quantities for 2022 were not available

Due to the complexity of our systems, it is necessary to provide customers with targeted advice on-site. Systems are developed and optimized jointly in some cases. We also support our customers in training employees. As a rule, this requires corresponding travel activity by our employees. Most of our customers are based outside of Germany, which affects the kilometers traveled and the choice of transport.

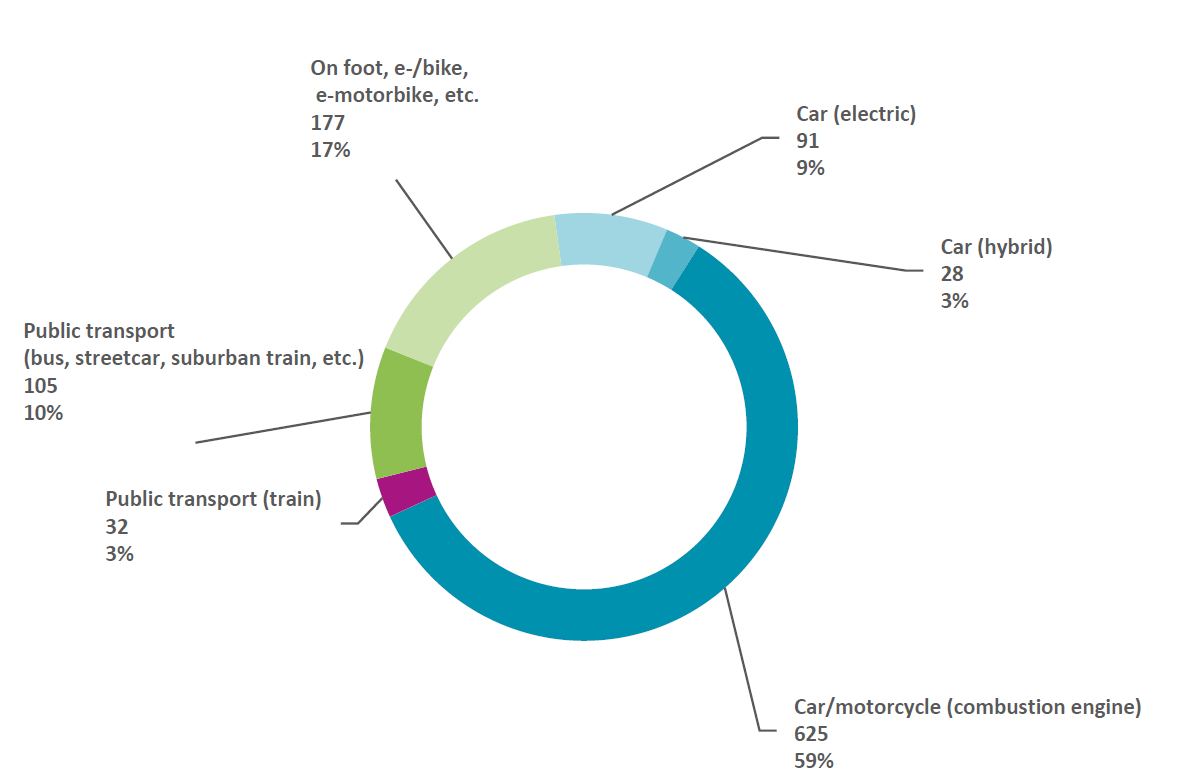

In the 2023 reporting year, we once again conducted a global survey on work commuting behavior among all employees. The extrapolation turned out that 41% of the Group’s employees come to work sustainably: 17% walk or use a bicycle/e-bike, 13% use public transport and 11% rely on vehicles with alternative drives - be it hybrid - 3% or purely battery electric vehicles 8%. At 59%, however, the majority still uses vehicles with classic combustion engines.

We have a total of 15 e-car charging stations and 24 e-bike charging stations on our company premises in Herzogenrath.

Number of employees per means of transport and the shares in % (extrapolation from survey with the average headcount 2023)

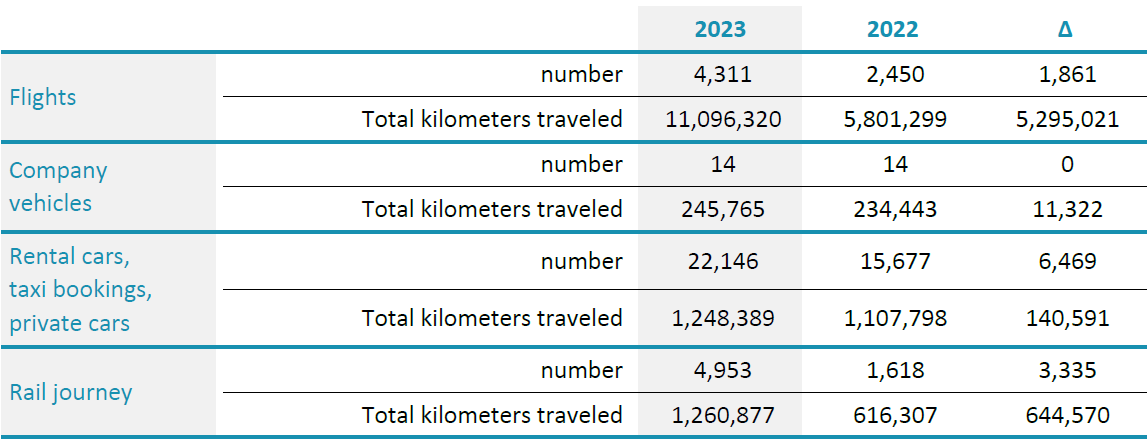

Traveling by plane cannot always be avoided as we sell our systems and technologies worldwide. However, we are trying to limit our air travel to what is necessary. For intercontinental travel, however, they are the only viable option in day-to-day business. In the reporting year 2023, there were 4,311 bookings (2022: 2,450).

A total of 11,096,320 kilometers were flown (2022: 5,801,299 km), an increase of 91% compared to 2022.

The reason for this increase compared to 2022 is the relaxed travel restrictions in connection with the corona pandemic.

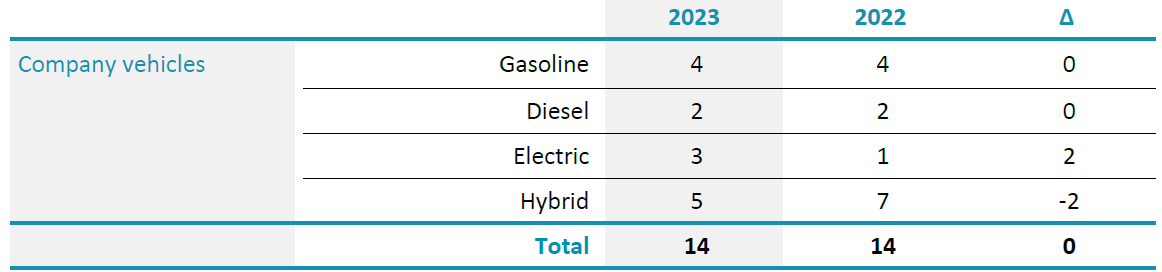

End of 2023, our company fleet consisted of 14 cars (2022: 14), two diesel-powered vehicle, four four gasoline-powered vehicles, five hybrid-powered vehicles, and three purely electric vehicle. Since 2020, in accordance with our internal guidelines, we have limited ourselves to hybrid and electric cars when purchasing new company vehicles. In 2023, compared to 2022, no vehicles with pure combustion engines were added. The number of vehicles with hybrid drives fell by two vehicles while two new electrically powered vehicles were added compared to 2022.

A total of 245,765 km were driven last year (2022: 234,443 km).

In the 2023 reporting year, our employees traveled a total of 1,248,389 km with a rental car, taxi, or private car (2022: 1,107,798 km).

We encourage our employees to travel by train whenever possible on business trips. While employees traveled 616,307 km by train in 2022, in the 2023 reporting year, the distance increased to 1,260,877 km, which corresponds to an increase of 105%.

Mobility metrics

Alan Tai

Taiwan/Singapore

Christof Sommerhalter

USA

Christian Geng

Europe

Hisatoshi Hagiwara

Japan

Nam Kyu Lee

South Korea

Wei (William) Song

China

AIXTRON SE (Headquarters)

AIXTRON 24/7 Technical Support Line

AIXTRON Europe

AIXTRON Ltd (UK)

AIXTRON K.K. (Japan)

AIXTRON Korea Co., Ltd.

AIXTRON Taiwan Co., Ltd. (Main Office)

AIXTRON Inc. (USA)

Christoph Pütz

Senior Manager ESG & Sustainability

Christian Ludwig

Vice President Investor Relations & Corporate Communications

Ralf Penner

Senior IR Manager

Christian Ludwig

Vice President Investor Relations & Corporate Communications

Prof. Dr. Michael Heuken

Vice President Advanced Technologies